Cheese spread is a soft, spreadable cheese or processed cheese product. It is typically made by blending one or more varieties of cheese with other ingredients such as vegetables, fruits, meats, and various seasonings. The addition of a liquid such as water, milk, or cream helps to achieve a smooth and spreadable consistency. Cheese spreads can be made at home using leftover cheeses, and they are often served as appetizers or snacks with crackers, bread, toast, or vegetables.

| Characteristics | Values |

|---|---|

| Ingredients | One or more varieties of cheese, water, milk, cream, garlic, wine, lemon juice, herbs, seasonings, emulsifiers, food stabilizers, sweeteners, salt, etc. |

| Recipe | Blend cheese and other ingredients until smooth. |

| Preparation Time | 15 minutes to make, 30 minutes to chill. |

| Storage | Store in an airtight container in the fridge for up to 3-7 days. |

| Serving Suggestions | Spread on bread, toast, crackers, vegetables, or use as a dip. |

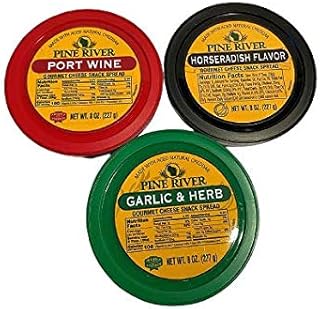

| Variants | Beer cheese spread, pimento cheese, port wine cheese, pub cheese, benedictine, cold pack cheese, cup cheese, etc. |

Explore related products

What You'll Learn

Cheese spread ingredients

Cheese spread is typically made by blending one or more varieties of cheese with other ingredients to create a creamy, spreadable texture. The beauty of making cheese spread at home is that you can use any variety of leftover cheese. This is a great way to reduce food waste and get creative with your favourite cheeses and flavour combinations.

The base of your cheese spread will be a blend of one or more cheeses. You can use a food processor or blender to mix your cheeses with other ingredients to create a smooth, creamy texture. Fresh herbs are a popular addition to cheese spread, adding depth of flavour and a medley of flavours. Garlic is also a common ingredient, adding a kick of flavour.

To help bind your cheese spread together, you can add a liquid such as water, milk, cream, or even wine. You can also add a little lemon juice to enhance the flavour. If you're making a pub cheese spread, you can add beer to your blend of cheeses.

You can also add seasonings and flavourings to your cheese spread. Mustard, hot sauce, salt, and pepper are all popular additions, as well as fresh chives. If you're making a pimento cheese spread, you might add prepared horseradish.

If you're looking for a reduced-fat option, you can make a cheese spread with a small amount of basic or bouillon-like taste, normally found in yeast extracts. This can help to intensify the savoury character of the cheese spread without adding extra fat.

History of Bronco Cheese Graters: When Were They Made?

You may want to see also

Making cheese spread at home

Cheese spread is a soft, spreadable delight that can be made with one or more varieties of cheese. It can be easily made at home and is a great way to use up leftover cheese. You can add your own choice of ingredients to make a medley of flavours.

Ingredients

You will need three varieties of cheese, including shredded cheese and cream cheese, and a little heavy cream to make it extra creamy. You can use any variety of leftover cheese, such as mozzarella or homemade fresh cheese. You can also add fresh herbs, garlic, lemon juice, and white wine.

Method

Place the cheeses and garlic in a food processor and pulse until it forms coarse crumbs. Add in your choice of seasonings, such as mustard, hot sauce, salt, and Worcestershire sauce. With the processor on, slowly stream in the liquid (beer, lemon juice, or water) until the mixture is smooth and mousse-like. This should take about 5 minutes.

Serving Suggestions

Scrape the mixture into a bowl and refrigerate for at least 30 minutes. Take the cheese out of the fridge and let it sit for 10 minutes before serving so that it softens a bit. Serve with crackers, vegetables, or bread. The cheese spread will stay fresh in an airtight container in the fridge for up to a week.

Bacon Cheese: How is This Deliciousness Made?

You may want to see also

Commercially packaged cheese spread

The specific process and ingredients used in commercially packaged cheese spread can vary depending on the manufacturer and the desired flavour and texture. Some common ingredients used in commercial cheese spreads include:

- Multiple types of cheese: Shredded or fresh cheese, such as mozzarella or cheddar, is often used to create a creamy texture and add flavour.

- Cream, milk, or cream cheese: These ingredients add richness and contribute to the spreadable consistency.

- Spices and seasonings: Common additions include garlic, mustard, hot sauce, salt, and herbs such as basil.

- Liquids: Water, wine, lemon juice, or beer may be added to adjust the consistency and enhance flavour.

- Emulsifiers and stabilizers: Ingredients like potassium phosphate, tartrate, carrageenan, and xanthan gum can be added to improve texture and prevent separation.

After blending the ingredients, the cheese spread is typically packaged into small foil-wrapped triangles or squares, which are then grouped together in cardboard containers, as seen with brands like Dairylea and The Laughing Cow. Alternatively, it can be packaged in pressurized cans, allowing the product to be dispensed in a string-like form, similar to the product Easy Cheese.

Panela Cheese: A Traditional Craft From Milk Curds

You may want to see also

Explore related products

Different types of cheese spread

Cheese spread is a soft, spreadable cheese or processed cheese product. It is typically made by blending one or more varieties of cheese with other ingredients to create a creamy spread. The cheeses are blended until smooth, and additional liquids such as water, milk, or cream are often added to improve spreadability. Cheese spreads can be made with almost any variety of cheese, including mozzarella, and can be served with crackers, vegetables, bread, or toast. They can also be used as a dip.

There are several different types of cheese spread, including those made with a single variety of cheese and those made with multiple cheeses. Some common additional ingredients used in cheese spreads are fruits, vegetables, meats, spices, and seasonings. For example, the "pub cheese" variety of cheese spread, a traditional bar snack in the United States, is made with beer as an additional ingredient. Another type of cheese spread that is popular in the Southern United States is pimento cheese, which has been referred to as the "pâté of the south" and "Carolina caviar." Port wine cheese is also mass-produced in the United States under several brands.

Reduced-fat cheese spreads are available for those who are conscious of their fat intake, and these have been shown to have a more savoury taste. Cheese spreads can be commercially packaged in many ways, including in small foil-wrapped triangles or squares grouped together in a cardboard container, such as Dairylea or The Laughing Cow, or in a pressurized can, such as Easy Cheese, which comes out in a string-like form.

Dairy-Free Cheese: What's the Secret Ingredient?

You may want to see also

Cheese spread taste and texture

Cheese spread is typically made by blending one or more varieties of cheese with other ingredients to create a soft, spreadable texture. The addition of liquids such as water, milk, or cream helps to achieve the desired creamy consistency. The taste and texture of cheese spread can vary depending on the types of cheese and ingredients used, as well as the method of preparation.

When blending leftover cheeses, adding a small amount of liquid helps to create a smooth and spreadable texture. The type of liquid used can vary, with options including water, milk, cream, or even beer. The choice of liquid can subtly influence the flavour and richness of the cheese spread. For example, milk and cream will contribute to a richer, more decadent taste and mouthfeel.

The variety of cheeses used in the spread also plays a significant role in determining the final taste and texture. Different cheeses have distinct flavours and melting properties, which can affect the overall creaminess and flavour profile of the spread. For instance, a blend of shredded cheese, cream cheese, and heavy cream will result in an especially creamy and rich cheese spread.

Additional ingredients such as herbs, spices, and seasonings are often incorporated to enhance the flavour and texture of the cheese spread. Fresh herbs, in particular, can add depth and elevate the overall taste experience. Garlic is also a popular addition, providing a pungent kick to the spread. Other ingredients like mustard, hot sauce, and Worcestershire sauce can be included to create more complex and nuanced flavours.

The texture of cheese spread is an important aspect of its appeal. A smooth and creamy texture is generally preferred, allowing for easy spreading on crackers, bread, or vegetables. To achieve this, the cheese and other ingredients are typically blended or processed until a mousse-like consistency is reached. The spread is then refrigerated, which helps to firm it up slightly and enhance its spreadability.

Artificial Cheese: What's It Made Of?

You may want to see also

Frequently asked questions

Cheese spread is made by blending one or more varieties of cheese with other ingredients to make a creamy spread. This can include other cheeses, vegetables, fruits, meats, and various seasonings.

To make a basic cheese spread at home, blend your leftover cheeses with a bit of liquid (water, milk, or cream) until the mixture is very smooth. You can add fresh herbs, garlic, and white wine to taste.

Homemade cheese spread will last in the fridge for up to one week. Store it in an airtight container and let it come to room temperature for 10 minutes before serving.