Irish Porter Cheese is a pasteurized cow's milk cheese produced in Ireland. It was first made by the Cahill family in 1982 at Cahills Farm Cheese. The cheese is crafted from cow's milk and aged for 10 months, resulting in a marbled appearance with a smooth texture. The distinctive feature of this cheese is its infusion with Irish porter beer, giving it a strong, stout flavour with hints of caramel and roasted barley.

| Characteristics | Values |

|---|---|

| Main Ingredients | Cow's milk, Guinness-brewer Porter, salt, starter cultures, vegetarian rennet, caramel (natural colour) |

| Texture | Dense, smooth, creamy |

| Taste | Strong dark flavours of aged cheddar and Irish beer, caramel and smoky undertones, malty, hints of roasted barley |

| Colour | Striking marbled pattern |

| Manufacturer | Cahills Farm Cheese, J.O.D. Foods |

| Brand Name | Old Irish Creamery |

| Awards | Silver medal at the World Cheese Awards 2011 |

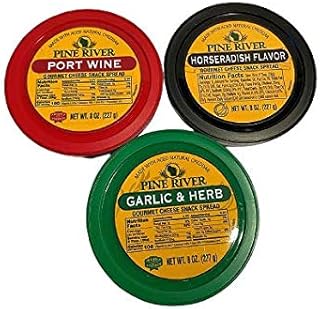

Explore related products

What You'll Learn

Irish Porter Cheese is crafted from cow's milk

Irish Porter Cheese is made with genuine Guinness-brewer Porter, which gives it a distinctive marbled pattern and a strong beer flavour. The marbling of the cheese comes from the caramel colouring, which also lends it a smoky, caramelized flavour. This artisanal cheese combines the rich, creamy texture of traditional Irish Cheddar with the bold, robust notes of Porter beer. The result is a harmonious fusion of savoury and malty flavours, with hints of caramel and roasted barley.

Irish Porter Cheese is an award-winning, pasteurized cow's milk cheese. It has a smooth texture and a striking marbled appearance, making it a perfect addition to any cheeseboard. The cheese has won a silver medal at the World Cheese Awards 2011. Irish Porter Cheese is also available from other producers, such as Grandpa's and Ireland's Own. These cheeses also emphasize the strong, stout flavour of the cheese, which pairs well with crackers and snacks.

Great Lakes Cheese: Wausau's New Dairy Delights

You may want to see also

It is aged for 10 months

Irish Porter Cheese is aged for 10 months to develop its distinct flavour and texture. This lengthy ageing process is a key step in the cheese-making process, contributing to its characteristic savoury and malty taste profile. The cheese is crafted from cow's milk, specifically pasteurised milk, and carefully aged over this period to achieve the desired result.

During the ageing process, the cheese wheels are carefully monitored and stored in optimal conditions to ensure the development of the desired flavour and texture. The temperature and humidity levels are controlled to promote the growth of beneficial bacteria and mould cultures, which contribute to the unique characteristics of Irish Porter Cheese.

The 10-month ageing period allows the flavours of the cheese and porter beer to meld and mature harmoniously. The beer infuses into the cheese, creating a marbled appearance and adding a robust, malty dimension to the creamy Irish cheddar. This fusion results in a savoury flavour profile with hints of caramel and roasted barley, making it a delightful treat for the taste buds.

The ageing process also contributes to the texture of the cheese. Over time, the cheese becomes denser and smoother while retaining a slightly crumbly quality characteristic of cheddar cheeses. This contrast between the creamy mouthfeel and the slight crumble creates a unique sensory experience, making Irish Porter Cheese a favourite among cheese enthusiasts.

By ageing the cheese for 10 months, the cheesemakers ensure that each bite delivers a complex interplay of flavours and textures, making Irish Porter Cheese a true delicacy. This ageing duration is specifically tailored to strike a balance between the sharpness of the cheddar and the subtle notes of the porter beer, resulting in a cheese that is both bold and refined.

The Gouda Cheese-Making Process at Castello

You may want to see also

It is infused with Irish porter beer

Irish porter cheese is a variety of cheese that is infused with Irish porter beer. This artisanal cheese is crafted from cow's milk and carefully selected and graded cheddar from the lush pastures of Ireland. The addition of porter beer gives the cheese a distinctive marbled appearance, with a smooth or dense yet creamy texture. The beer also imparts bold, robust, and stout flavours to the cheese, creating a harmonious fusion of two quintessential Irish flavours.

The process of infusing the cheese with Irish porter beer involves carefully incorporating the beer into the cheese curds during the cheesemaking process. This can be done by soaking the cheese curds in the beer or adding the beer to the milk during the curdling process. The specific techniques and recipes may vary among cheese producers, with some using Guinness-brewer Porter to give the cheese a strong dark flavour, while others aim for a more subtle hint of caramel and roasted barley.

One well-known producer of Irish porter cheese is Cahills Farm Cheese, who are credited with originating the variety in 1982. Their Original Irish Porter Cheese is crafted from cow's milk and aged for 10 months, resulting in a marbled cheese with a caramel and smoky undertone. Other producers, such as J.O.D. Foods under the brand name "Old Irish Creamery", have also created award-winning Irish porter cheeses, recognised at the World Cheese Awards 2011.

The infusion of Irish porter beer not only enhances the flavour of the cheese but also contributes to its unique appearance and texture. The beer's dark colour creates the marbled effect, while its robust flavour adds a savoury and malty dimension to the cheese. This combination of creamy Irish cheddar and porter beer makes Irish porter cheese a popular addition to cheeseboards and a perfect pairing for ale enthusiasts.

The Making of Roquefort Cheese: A Step-by-Step Guide

You may want to see also

Explore related products

It has a marbled appearance and texture

Irish Porter Cheese is a pasteurised cow's milk cheese produced by J.O.D. Foods in Kilmallock, Ireland, under the brand name "Old Irish Creamery". It was first crafted by the Cahill family in 1982 and is made with genuine Guinness-brewer Porter. The cheese is aged for 10 months and has a striking marbled appearance and smooth texture.

The marbling effect is created by infusing the cheese with rich Irish porter beer, which gives it a bold, robust flavour. This artisanal cheese combines the rich, creamy texture of traditional Irish Cheddar with the malty, savoury notes of porter beer. The result is a harmonious fusion of two quintessential Irish flavours.

The marbled pattern is the most visually attractive part of the cheese, with its swirls of dark and light colours. The dark swirls come from the infusion of porter beer, which also imparts a strong, stout flavour to the cheese. The light-coloured sections are the natural colour of the cheddar cheese, which is made from cow's milk, salt, starter cultures, and vegetarian rennet.

The marbling not only adds to the visual appeal of the cheese but also enhances its flavour and texture. The dark swirls of porter beer create a smooth, creamy mouthfeel, while the light sections offer a denser, more chewy texture. The two textures contrast and complement each other, creating a unique sensory experience.

The Ancient Origins of Cheddar Cheese

You may want to see also

It is made by Cahills Farm Cheese in Ireland

The Original Irish Porter Cheese is crafted from cow's milk at Cahills Farm Cheese in Ireland. The Cahill family has been farming the lush green pasturelands of Newcastle West in County Limerick since 1902, making them one of the oldest artisanal cheese-making families in the country. They use time-honoured methods and recipes passed down through the generations to create their speciality cheddar cheese, which is matured to perfection.

Cahills Farm Cheese is proud to use only 100% natural, locally sourced ingredients, with their cheddar made using pasteurised milk from grass-fed cows. Their commitment to quality and tradition has resulted in global recognition for their cheese, including a Gold Star from the Guild of Fine Foods and Silver medals at both the Great Taste Awards and the Mondial du Fromage.

The Original Irish Porter Cheese is a testament to the Cahill family's cheese-making expertise. This variety is aged for 10 months, resulting in a marbled cheese with a dense yet smooth texture. The secret behind its unique flavour lies in the infusion of rich Irish porter, imparting caramel and smoky undertones that complement the aged cheddar perfectly. The use of Guinness-brewer Porter gives it a distinctively stout and hearty flavour.

David and Marion Cahill, the heart of Cahills Farm Cheese, began their journey by creating a range of handcrafted soft cheeses, yogurts, and farmhouse butter, which they sold through local shops and markets. As their family grew, so did their business, with all seven of their children playing a role in the company's success. Today, Cahills Cheese continues to innovate, combining traditional methods and original family recipes with modern technology to create exceptional cheeses, including the beloved Original Irish Porter Cheese.

Hedgehog Cheese: A Spiny Dairy Delight Explained

You may want to see also

Frequently asked questions

Irish Porter Cheese is made from cow's milk, Guinness-brewer Porter, salt, starter cultures, and vegetarian rennet.

Irish Porter Cheese is handcrafted and pasteurized. It is aged for 10 months and has a smooth texture with a distinctive marbled pattern.

Irish Porter Cheese has a strong, dark, and savory flavor with hints of caramel, roasted barley, and a stout porter taste.

Irish Porter Cheese is made by J.O.D. Foods, under the brand name "Old Irish Creamery". It was originally invented by the Cahill Family in 1982.