Parmesan cheese is traditionally made from cow's milk and is aged for at least 12 months. The process of making Parmesan cheese involves heating a combination of whole milk and naturally skimmed milk in copper vats, with additional ingredients like whey and rennet added to form the curd. The cheese is then aged in these copper vats, creating a distinct sweet taste through the natural fermentation of cow's milk. In this response, we will delve into the specific steps and techniques employed in the creation of this beloved Italian cheese.

Explore related products

What You'll Learn

Parmesan is traditionally made from cow's milk

The traditional method of making Parmesan cheese involves using rennet, a natural enzyme found in the stomachs of young mammals, which helps them digest their mother's milk. This ingredient has made traditionally made Parmesan unsuitable for vegetarians and those following a halal diet. However, some producers are now using microbial rennet, or "vegetarian rennet", to create vegetarian- and halal-friendly Parmesan.

The type of milk used is an important factor in the taste and texture of Parmesan. Parmesan is traditionally made with whole milk and naturally skimmed milk, which gives it a lower fat content than similar cheeses like Pecorino, which is made from sheep's milk. The milk used to make Parmesan may come from cows fed on silage or grass, and it can be a combination of milk from several different days.

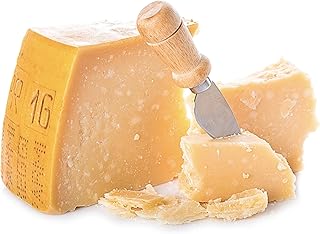

The length of time that Parmesan is aged for also affects its flavour and texture. While traditional Parmesan is aged for at least 12 months, some varieties are aged for longer to create a sweeter taste. For example, Copper Kettle Parmesan is aged for 16 months in copper vats, which gives it a distinctly sweet flavour.

The production of Parmesan is highly regulated, particularly in Europe, where the term "Parmesan" is legally protected and can only be used to refer to Parmigiano Reggiano, which must be made in a restricted geographic area using specific methods. However, outside of Europe, the name "Parmesan" has become genericised, and can refer to a variety of hard Italian-style grating cheeses made from cow's milk.

Jamaican Cheese: Traditional Making Process Explained

You may want to see also

Rennet, a natural enzyme, is added to form the curd

Parmesan cheese is traditionally made from cow's milk. Whole milk and naturally skimmed milk are combined and then distributed into copper vats for heating. During the two-step heating process, additional ingredients like whey and rennet are added to form the curd.

Rennet is a natural enzyme that plays a crucial role in the cheese-making process. It is found in the stomachs of young mammals, aiding in the digestion of their mother's milk. In the context of Parmesan cheese production, rennet is added to the heated milk to initiate the formation of curds. This step is essential for transforming the liquid milk into a solid form, which is a fundamental aspect of cheese-making.

The addition of rennet causes the milk to coagulate and form a solid mass, separating into curds and whey. The curds are then cut and stirred gently to release moisture and encourage further curd formation. This process, known as "cheddaring," helps develop the texture and flavour of the final product.

The amount of rennet added and the coagulation time can vary depending on the quality of milk used. For instance, if using a better-quality, raw milk, the recipe suggests decreasing the rennet by 25-30% and reducing the coagulation time by 40-50%. Adjustments like these ensure the desired curd formation and contribute to the overall quality of the Parmesan cheese.

The curds are then collected and placed into moulds, where they are pressed and further drained of excess moisture. This step helps to create the characteristic firm texture of Parmesan cheese. The curds are then brined and aged, developing their signature sharp flavour and granular texture.

County Line Cheese: Where is it Made?

You may want to see also

It's aged for at least 12 months

Parmesan cheese is aged for a minimum of 12 months. This lengthy aging period is a key part of the traditional process of making this ancient and unique cheese. The aging time gives the cheese its distinctive flavour and texture. The longer the cheese is aged, the more intense the flavour. For example, Cello Copper Kettle Parmesan is aged for 16 months, which creates a distinctly sweet taste.

The aging time is also important for the cheese's authenticity. In Europe, the term Parmesan is legally protected and can only be used to refer to Parmigiano Reggiano, which must be made in a restricted geographic area, using stringently defined methods. This includes the length of aging, which must be a minimum of 12 months. Special seals are used to identify the product as authentic, with the identification number of the dairy, the production month and year, a code identifying the individual wheel, and stamps regarding the length of aging.

The aging time for Parmesan varies outside of Europe. In the US, for example, there is no restriction on aging time. Some American generic Parmesan is sold already grated and has been aged for less than 12 months. In Canada, regulations only define moisture and fat levels, with no restriction on aging time.

The aging process is also influenced by the type of milk used. Parmesan is traditionally made from cow's milk, but other types of milk can be used, such as sheep's milk, which contains more fat. The quality of the milk also matters; raw milk requires different adjustments to pasteurized milk, such as decreasing the amount of rennet and coagulation time.

The Making of Cheese: A TV Show Documentary

You may want to see also

Explore related products

Grana Padano is an Italian cheese similar to Parmigiano Reggiano

Grana Padano and Parmigiano Reggiano are two of Italy's most well-known cheeses. They share many similarities, but also have distinct differences. Both are PDO (Protected Designation of Origin) cheeses, which means they can only be made in certain places and must follow specific rules. Grana Padano has a much larger production area than Parmigiano Reggiano, covering several regions of Northern Italy, including Piedmont, Veneto, Lombardy, Emilia Romagna, and Trentino Alto-Adige. The production area for Parmigiano Reggiano is more localized, encompassing the cities of Parma, Reggio Emilia, Modena, Bologna, and Mantova.

Grana Padano is Italy's most-produced cheese, with about 24% of the country's milk production used to make it. It is made with partially skimmed raw milk from cows that are milked twice a day, and the milk arrives at the cheesery 24 hours after milking. The cows are allowed to feed on 50% grain matter in addition to grass-feeding, resulting in a slightly fattier and sweeter milk. Grana Padano has a lower fat content than Parmigiano Reggiano and matures more quickly, with a minimum aging time of 9 months. It has a softer, butterier, and slightly more delicate flavour.

Parmigiano Reggiano, on the other hand, is made from a mix of whole and skimmed milk. The whole milk is milked the same morning, while the skimmed milk is milked the evening before and skimmed overnight. The milk must be delivered to the cheesery within two hours of milking and must remain above 18°C to maintain the bacteria that ripen the cheese. The cows providing the milk for Parmigiano Reggiano must only feed off grass and cereals grown in the area. It takes a minimum of 12 months to mature and has a stronger, more complex, nuttier, and saltier taste than Grana Padano.

In terms of flavour, the preference between the two cheeses depends on their aging and the dish they are served with. Grana Padano is typically used in cooking, while Parmigiano Reggiano is often grated on top of a dish.

Crafting Cheese Wheels: The Art of Curd Transformation

You may want to see also

Parmesan is low in lactose

Parmesan is a hard, granular cheese produced from cow's milk and aged for at least 12 months. It is traditionally made by combining whole milk and naturally skimmed milk, which is then heated in copper vats. During this two-step heating process, additional ingredients like whey and rennet are added to form the curd. The long aging process, which can be up to 16 months, gives Parmesan its distinct flavour and texture.

While Parmesan is made from milk, a food that typically contains lactose, the process of making Parmesan cheese reduces the lactose content. Lactose is a type of sugar found in milk, and it is reduced or eliminated in the cheesemaking process. This is because the bacteria used to make cheese consume the lactose present in the milk. The longer a cheese is aged, the lower the lactose content, as the bacteria have more time to break down the lactose.

The aging process of Parmesan cheese, which is typically between 12 and 16 months, means that most of the lactose present in the milk is broken down. This makes Parmesan a low-lactose food, which can be beneficial for individuals with lactose intolerance or those looking to reduce their lactose consumption.

Additionally, the type of milk used to make Parmesan can also impact its lactose content. Parmesan is traditionally made with cow's milk, which has a higher lactose content than other types of milk, such as sheep or goat's milk. However, the aging process significantly reduces the lactose content, making it suitable for those with lactose sensitivity.

It is important to note that while Parmesan is low in lactose, it may not be completely lactose-free. The aging process reduces the lactose content to very low levels, but trace amounts may still be present. For individuals with severe lactose intolerance or dairy allergies, even small amounts of lactose can trigger symptoms. Therefore, it is always recommended to consult with a healthcare professional or a dietician for personalised advice regarding dietary restrictions and to check the labels of any purchased Parmesan cheese.

The Moon: Green Cheese and Its Meaning

You may want to see also

Frequently asked questions

Parmesan is traditionally made from cow's milk.

Parmesan is typically aged for at least 12 months. However, some varieties are aged for longer, up to 16 months, to create a sweeter flavour.

Whole milk and naturally skimmed milk are combined and heated in copper vats. During this two-step heating process, additional ingredients like whey and rennet are added to form the curd.

Grana Padano, Pecorino Romano, and Piave are all similar to Parmesan in terms of taste and texture. However, the main differences lie in the production methods, aging times, and the type of milk used. For example, Pecorino is made from sheep's milk, while Parmesan is made from cow's milk.