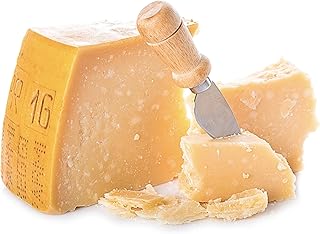

Parmesan cheese, or Parmigiano Reggiano, is a semi-hard Italian cheese with a granular texture. It is made from unpasteurised cow's milk, which is mixed with skimmed milk and pumped into copper-lined vats. The cheese is then aged for at least 12 months, with a minimum of 9-10 months in some places, and can be aged for up to 20 months. The length of ageing affects the flavour, which is always slightly salty, buttery, grassy, and nutty, with notes ranging from acidic to fruity. The name Parmigiano Reggiano is protected by law and can only be used for cheese produced in certain provinces in Italy, although outside of the EU, the name Parmesan can be used for imitations.

| Characteristics | Values |

|---|---|

| Ingredients | Milk, salt, and rennet |

| Milk Type | Unpasteurised cow's milk |

| Milk Storage | Stored for at least 12 months |

| Milk Mixture | Whole milk from morning milking mixed with naturally skimmed milk from the previous evening |

| Vat Type | Copper-lined |

| Aging | Minimum of 12 months, averaging 20 months |

| Texture | Semi-hard, slightly firmer than aged cheddar |

| Taste | Salty, buttery, grassy, nutty, acidic, fruity, or piquant |

| Production Location | Italy, specifically the provinces of Parma and Reggio Emilia |

| Manufacturer | Parmigiano Reggiano |

Explore related products

What You'll Learn

Ingredients: milk, salt, and rennet

Parmesan cheese, or Parmigiano Reggiano, is made with just three ingredients: milk, salt, and rennet. The milk used is unpasteurised cow's milk. The whole milk of the morning milking is mixed with the naturally skimmed milk of the previous evening's milking, resulting in a part-skim mixture. This mixture is then pumped into copper-lined vats, which heat evenly and contribute copper ions to the mix.

The milk is stored for at least 12 months before being made into Parmesan cheese. This long ageing process gives Parmesan its distinctive texture and flavour. The minimum ageing time varies depending on the region and style of Parmesan being produced. For example, in the United States, Parmesan must be cured for at least 10 months, while in Canada, there is no restriction on ageing time.

Salt is added to the milk mixture to enhance the flavour and improve the texture of the cheese. The salt used is typically pure and unadulterated, with no added chemicals or preservatives. This helps to ensure the cheese develops its characteristic salty flavour during ageing.

Rennet is a natural enzyme that makes milk curdle, and it is used in almost all aged cheeses. It is essential for the cheese-making process, as it causes the milk to separate into solid curds and liquid whey. The curds are then drained and pressed to form the solid cheese wheel. The whey is drained off and can be used for other purposes, such as feeding livestock or making ricotta cheese.

In addition to these three main ingredients, the cows' diet and the local terrain also play a role in the unique flavour of Parmesan cheese. The cows that produce the milk for Parmigiano Reggiano are fed a specific diet, and the terrain of the Italian provinces of Parma and Reggio Emilia, where the cheese is traditionally made, also contributes to the distinct taste of the cheese.

The Magic Ingredients Behind Nacho Cheese Sauce

You may want to see also

Milk storage: 12 months minimum

The process of making real Parmesan cheese, or Parmigiano Reggiano, is a complex and time-consuming one. One of the most critical steps in the production of this Italian delicacy is the lengthy storage period of the milk used. Indeed, the milk must be stored for a minimum of 12 months before it can be transformed into the iconic cheese.

This extended storage period is a key factor in the overall quality and flavour of the final product. During this time, the milk is carefully maintained at a constant temperature to ensure its freshness. This stage of the process is crucial, as it allows the milk to develop the complex flavours that will eventually characterise the cheese.

The milk used for Parmigiano Reggiano is sourced from cows grazing in the provinces of Parma and Reggio Emilia, in the Emilia-Romagna region of Italy. The unique terrain and climate of this region contribute to the distinct flavour of the milk, which is further enhanced by the traditional methods employed during the storage process.

The lengthy storage period also serves another important purpose. In the Middle Ages, when Parmesan cheese was first created by Benedictine monks, one of their primary goals was to extend the shelf life of the abundant milk produced by their cows. By storing the milk for an extended period, the monks could ensure a longer-lasting product, thereby reducing waste and providing a valuable source of nutrition for the community.

Today, the 12-month storage period is a standard requirement for the production of authentic Parmigiano Reggiano. This strict regulation helps to ensure the quality and authenticity of the cheese, setting it apart from imitations that may not adhere to the same rigorous standards.

Cheese Balls: Who Invented This Snack?

You may want to see also

Mixing and heating: copper-lined vats

Once the milk has been collected and stored for at least 12 months, it is pumped into copper-lined vats. Copper is an excellent conductor of heat, and the copper-lined vats ensure that the milk mixture is heated evenly. The copper also contributes copper ions to the mixture, which is important for the cheese's flavour and texture.

The heating process is a crucial step in the cheese-making process, as it causes the milk proteins to denature and form curds. This process is essential for separating the solids (curds) from the liquids (whey). The copper vats are carefully heated to a specific temperature, which can vary depending on the cheese maker's preferences and the desired characteristics of the final product.

During this stage, the milk mixture is carefully stirred and agitated to ensure even heating and to prevent scorching. The cheese maker must be vigilant and constantly monitor the temperature and consistency of the mixture. This step requires experience and expertise, as overheating or uneven heating can affect the quality of the final product.

The heating and mixing process in the copper-lined vats can take several hours, depending on the batch size and the desired characteristics of the Parmesan cheese. This step is crucial in developing the complex flavours and unique texture that Parmesan cheese is known for.

The Art of Bulgarian Feta: A Traditional Cheese-Making Journey

You may want to see also

Explore related products

Aging: 12 months minimum

The final step in the process of making real Parmesan cheese is aging the cheese for a minimum of 12 months. This is a requirement for the cheese to be labelled "Parmigiano Reggiano". A one-year-old Parmesan will have a smooth texture and a mild flavour, making it ideal for grating or incorporating into cooked dishes.

The length of the aging process is an important factor in determining the quality of the cheese. While 12 months is the minimum requirement for Parmigiano Reggiano, the cheese is often aged for longer, with an average of 20 months. The longer the cheese is aged, the more complex its flavour and texture become. For this reason, specialty stores often sell older versions of Parmesan, which are ideal for eating on their own.

The aging process also affects the price of the cheese. Older cheeses are generally more expensive due to the longer production time and more complex flavour. As such, the aging time is often included on the cheese's packaging, allowing consumers to make an informed decision about the quality and flavour they are purchasing.

The length of aging also determines the suitability of the cheese for different dishes. Younger cheeses, aged for around 12 months, are milder in flavour and therefore better suited for cooking or grating. Older cheeses, on the other hand, have a stronger flavour and a more granular texture, making them ideal for adding a burst of flavour to dishes or even for eating on their own.

The aging process itself is carefully controlled to ensure the cheese develops the desired flavour and texture. This includes regulating factors such as temperature, humidity, and ventilation in the aging rooms. The cheese is also regularly inspected and rotated to ensure even aging and to check for any defects.

How Much Milk Goes Into Cheese Production?

You may want to see also

Authentic Parmesan: made in Italy

Authentic Parmesan cheese, or Parmigiano Reggiano, is made in Italy, predominantly in the provinces of Parma and Reggio Emilia, but also in Bologna, Modena, and Mantua. The name Parmigiano Reggiano is protected by law and refers exclusively to the Parmigiano Reggiano PDO cheese manufactured in northern Italy.

The cheese is made from unpasteurised cow's milk. The whole milk of the morning's milking is mixed with the naturally skimmed milk of the previous evening, resulting in a part-skim mixture. This mixture is then pumped into copper-lined vats, which heat evenly and contribute copper ions to the mix. The milk used in Parmigiano Reggiano is stored for at least 12 months before production begins. The long storage period is necessary because it takes time for the milk to develop the unique terrain flavours characteristic of authentic Parmigiano Reggiano.

Parmigiano Reggiano is a semi-hard cheese with a creamy body and a unique, almost effervescent texture. Its flavour varies depending on how long it has been aged and the season in which it was produced, but it is always slightly salty, buttery, grassy, and nutty, with subtle notes ranging from acidic to fruity to piquant.

To be labelled "Parmigiano Reggiano", the cheese must be aged for a minimum of 12 months. However, to be considered "long-aged", it should be aged for an average of 20 months. A one-year-old Parmesan will have a smooth texture and a mild flavour, best suited for grating or incorporating into cooked dishes. Older cheeses will have a more complex flavour and are ideal for eating on their own.

Cheese Ravioli: Unraveling the Perfect Blend of Ingredients

You may want to see also

Frequently asked questions

By law, Parmesan cheese may contain only three ingredients: unadulterated cow's milk, salt, and rennet, a natural enzyme that makes milk curdle.

Parmesan cheese is aged for at least 12 months. A one-year-old Parmesan will have a smooth texture and a mild flavor, best suited for grating or incorporating into cooked dishes.

Parmesan cheese is made in Italy, specifically in the provinces of Parma and Reggio Emilia.

True Parmigiano Reggiano will be labelled "made in" or "from" Italy, and often sport a PDO seal. A wheel of the real cheese will have its name, Parmigiano Reggiano, embossed permanently in a dotted step-and-repeat pattern all over the edge.