Soy cheese is a dairy-free, plant-based alternative to regular cheese. It is made through a process of curdling and coagulation, similar to tofu. Soy cheese is made by soaking and grinding soybeans, extracting the soy milk, and then cooking it to collect the cheese. The process of making soy cheese at home is simple and inexpensive, and the final product can be used in a variety of dishes, including cheesecakes, and as a cheddar-style cheese.

| Characteristics | Values |

|---|---|

| Ingredients | Soya beans, clean water, salt, calcium sulfate, coagulant (aldonic acid lactones, uronic acid lactones, glucono delta-lactone (GDL)), flavor-producing proteolytic enzyme, soy yogurt culture, herbs, spices |

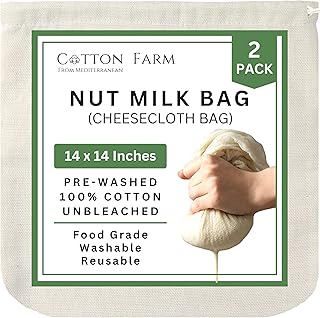

| Equipment | Mill, oven, cheese bag or cloth, knife |

| Process | Select, winnow, and sort good-quality grain; soak the soya beans in clean water; grind the grain in a mill; extract the soy milk; cook the soy milk; coagulate the protein to make curds; drain the whey; add salt and flavorings; mold, press, and coat with paraffin; age |

| Time | 2-8 hours to incubate yogurt; a few hours to drain whey; 2-3 months to age |

| Temperature | Boil milk; cool to 110°F; maintain broth at 50°C; cook curd at 55°C; age at 15°C |

Explore related products

What You'll Learn

Soy milk extraction

The first step in making soy cheese is to extract soy milk from soybeans. This process begins with the selection of high-quality soybeans, ideally the clear hylem variety, which is considered more flavorful than other soybeans. The soybeans are then soaked in water for several hours, with the temperature of the water depending on the desired outcome. Soaking in cooler water for a longer period of time, such as 6 to 12 hours, will produce a different result than soaking in warm water for a shorter period.

After soaking, the soybeans are ground into a milky slurry. This can be done using a number of grinders, which transform the beans into the desired consistency. At this stage, the slurry is placed in a centrifuge that extracts any insoluble bits of bean. The separated soy liquid, called jun, is then blended with vitamins, flavorings, and sugar. Vanilla, carob, chocolate, and almond are commonly added to enhance the flavor of the final product.

The jun is then injected into large tanks, where it undergoes further processing. It is heated and sterilized to prevent bacterial growth, as soybeans are a low-acid food susceptible to harmful bacteria. The hot milk is then cooled and packaged in a way that ensures it is never exposed to air, as this could introduce bacteria.

The soy milk extraction process is a key step in the production of soy cheese, as it provides the base ingredient for the cheese-making process. The extracted soy milk is then further manipulated to create a cheese-like product with a similar texture and body to traditional dairy cheese.

The Art of Mexican Cheese: Milk, Culture, and Flavor

You may want to see also

Fermentation

The process of fermenting soybeans typically begins with the soybeans being soaked and cooked. They are then inoculated with a specific type of mould, usually Aspergillus oryzae or Aspergillus sojae, to enable fermentation. This mixture is called "koji" and is fermented for 2-3 days. During this time, starches are broken down into simple sugars, proteins into amino acids, and oils into fatty acids. The koji must be mixed frequently to release the heat produced during fermentation, as the surrounding temperature can greatly impact the process.

After the initial fermentation, the koji is combined with water and salt, and further fermented with lactic acid bacteria and yeast to form a moromi, or solid-state mash. This secondary fermentation process can last for several months or even years and forms the hundreds of flavour molecules found in soy sauce. The longer the fermentation, the deeper the flavour profile, similar to ageing wine or cheese.

The secondary fermentation process is responsible for the diversity of soy sauce flavours, which can differ in sweetness, acidity, saltiness, aromaticity, texture, thickness, and intensity of caramelization. The predominant microbes involved in this stage include Tetragenococcus halophilus and Zygosaccharomyces rouxii, which contribute to the characteristic toasty, malty flavours of soy sauce.

In addition to soy sauce, other fermented soybean products include tempeh, miso, tofu, and natto. Tempeh is made by fermenting whole soybeans and results in a cake-like product with a nutty flavour and chewy texture. Miso is a paste produced from fermented soybeans that is commonly used as a seasoning in Japanese cuisine. Tofu can also be fermented, resulting in a product called "stinky tofu" that is a popular street food in Taiwan. Natto is a popular breakfast dish in Japan made from soybeans fermented with Bacillus Subtillis var. natto bacteria, which has potential health benefits such as inhibiting blood clots and reducing the risk of cardiovascular disease.

Goldfish Cheese: What's the Secret Ingredient?

You may want to see also

Coagulation

In the context of soy cheese-making, the liquid used is soy milk, which is obtained by soaking, grinding, and extracting the milk from soybeans. The soy milk is then cooked, and a coagulant is added to initiate the coagulation process and form the curd.

There are various coagulants that can be used in soy cheese production. One option is to use salts containing calcium and magnesium, such as calcium chloride or calcium sulfate. These salts promote coagulation by interacting with the proteins in the soy milk, leading to the formation of a solid curd.

Another type of coagulant used in soy cheese-making is glucono delta-lactone (GDL), a non-salt-based coagulant commonly found in commercially packaged tofu. GDL is an effective alternative for those seeking a non-salt option.

The choice of coagulant can impact the texture and body of the resulting soy cheese. For example, a soy cheese sample made with GDL exhibited a uniform texture and body, while a control sample made with calcium sulfate had a fragile and uneven texture.

Osceola Cheese: A Tasty Treat from Wisconsin

You may want to see also

Explore related products

Curdling

During curdling, the pH of the milk decreases, and it becomes more acidic. Independently floating casein molecules are attracted to each other and form "curdles" that float in a translucent whey. The curdling process occurs more rapidly at warmer temperatures compared to colder ones.

In the context of soy cheese, soy milk is curdled through a similar process. The curdling process is initiated by adding coagulants like enzymes or acids, causing the soy milk to separate into solid curds and liquid whey. These curds can then be pressed and further processed to create soy cheese.

Mac & Cheese: Wheat Pasta, Where's It Made?

You may want to see also

Flavouring

Soy cheese is made from soy milk and/or tofu, with tofu being curdled and coagulated soy milk. Soy protein isolate and some type of oil, like canola or soybean oil, are also sometimes added.

Soy cheese has a variety of flavours available, including American, Cream Cheese, Cheddar, Garlic and Herb, Mexican, Monterey Jack, Mozzarella, Parmesan, Pepper Jack, Provolone, and Swiss. The flavour of the cheese is determined by the type of soybean used, the storage temperature, the soy milk processing conditions, the stirring speed, the coagulation temperature, the type of coagulator, and the concentration ratio of the coagulator.

To improve the flavour of soy cheese, spices and other ingredients are added, or the soy milk is blended with other types of milk. Spices that can be added include roasted cumin seeds, red/green peppers, and herbs. The addition of milk cheese starters and non-starter cultures can also improve the flavour.

The beany flavour of soy cheese can be reduced by adding spices and other ingredients, or blending with other milk types. The reduction of lipoxygenases in soy milk helps to reduce rancidity and protect the odour.

Probiotic soy cheese types have also been developed to improve the nutritional quality and flavour of the cheese. These use microbes or coloured food ingredients like carrots to improve colour and nutrition.

Cheese Pull: Chain Pizza's Melty Topping Secrets

You may want to see also

Frequently asked questions

You will need soybeans, water, a mill, and a coagulant such as salt or glucono delta-lactone (GDL). You can also add vanilla extract, almond extract, and maple syrup for flavor.

First, select, winnow, and sort good-quality soybeans. Next, soak the soybeans in clean water, changing the water frequently. Then, grind the soybeans in a mill and extract the soy milk. Finally, cook the soy milk and collect the cheese.

Boil homemade or store-bought soy milk, stirring constantly. Then, pour it into a sterile jar, cover, and cool to 110 degrees Fahrenheit. After, add yogurt or a starter and stir until dissolved. Cover and incubate for 2-8 hours, keeping it as close to 110-115 degrees Fahrenheit as possible.

After making soy milk, add a coagulant such as salt or glucono delta-lactone to coagulate the milk and form curds. Then, cook the curds and drain the whey. Finally, add salt, mold, press, and age the curds to form soy cheese.