String cheese is a popular snack, especially for kids, and is made from mozzarella cheese. The manufacturing process aligns the proteins in the cheese, making it stringy. When mozzarella is heated to 60 °C (140 °F) and then stretched, the milk proteins line up, and it is then possible to peel strings or strips from the larger cheese. The strings themselves are formed from proteins aligning during the kneading process. The drier the cheese gets, the easier it is to pull apart.

| Characteristics | Values |

|---|---|

| Type of milk used | Milk from an aged goat or sheep |

| Seasoning | Black cumin and mahleb |

| Sold in the form of | Braided endless loop |

| String formation | Pulling during processing |

| String formation | Milk proteins line up when heated to 60 °C (140 °F) |

| String formation | Mechanical alignment of milk proteins |

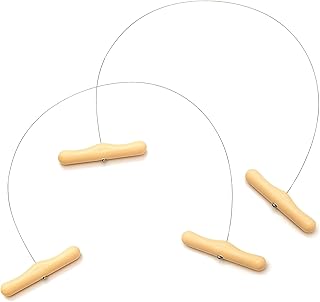

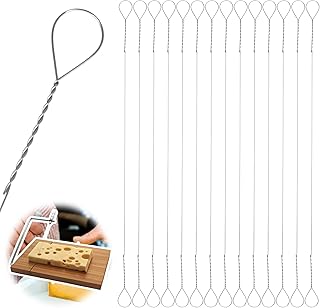

Explore related products

What You'll Learn

- Mozzarella is naturally stringy, and gets stringier with less milk fat and moisture

- The manufacturing process aligns the proteins in the cheese, making it stringy

- The strings are formed from proteins aligning during the kneading process

- The cheese is stretched and pulled by augers in a cooker stretcher while being heated to 60°C

- The type of milk used usually comes from an aged goat or sheep

Mozzarella is naturally stringy, and gets stringier with less milk fat and moisture

Mozzarella is naturally stringy, and this quality can be enhanced by reducing the milk fat and moisture content. The stretchiness of mozzarella is due to the presence of two proteins, casein and whey, which form a gel-like structure that traps water. This structure becomes more flexible when heated, allowing the cheese to stretch without breaking.

The process of making string cheese involves stretching and pulling the cheese while heating it to 140°F (60°C). At this temperature, the milk proteins move around and align horizontally, enabling them to form long chains that give the cheese its stringy texture.

Low-moisture mozzarella is often preferred for its superior melting properties compared to fresh mozzarella, which tends to exude water and become soupy when melted. The reduced moisture content in string cheese helps to maintain its stringy texture and prevents it from becoming soggy.

Additionally, the fat content of mozzarella also plays a role in its stringiness. Whole milk mozzarella, with a slightly higher fat content than part-skim or skim mozzarella, tends to have better meltability and stretchiness. The fat content contributes to the elasticity and gooeyness of the cheese, resulting in a more desirable texture.

Overall, the combination of reduced moisture and optimised fat content in mozzarella contributes to its natural stringiness, and further enhancements can be achieved through the cheesemaking process, resulting in the creation of string cheese.

The Mystery Behind American Cheese Slices: Ingredients Revealed

You may want to see also

The manufacturing process aligns the proteins in the cheese, making it stringy

The manufacturing process of string cheese involves aligning the proteins in the cheese, giving it its characteristic stringiness. This process is unique to mozzarella cheese, which is the base of string cheese.

Mozzarella is naturally stringy, and this property is enhanced by reducing milk fat and moisture content. When making string cheese, the curds are heated to 60 degrees Celsius or 140 degrees Fahrenheit. At this temperature, the milk proteins move around and align in a row, allowing the cheese to be peeled into strips or strings.

The cheese is then stretched and pulled by augers in a cooker stretcher while being heated to 60 degrees Celsius. This mechanical process further aligns the milk proteins, making them stretchy. From the cooker stretcher, the cheese is pumped into an extruding machine that shapes it into the familiar tubular form.

The drier the mozzarella cheese becomes, the easier it is to stretch and pull apart. This is why string cheese, which has been significantly stretched and dried out, naturally forms strings when pulled. The manufacturing process of string cheese thus involves manipulating the protein structure of mozzarella through heating, stretching, and drying, resulting in its unique stringy texture.

Cheese Wheel: A Historical and Practical Decision

You may want to see also

The strings are formed from proteins aligning during the kneading process

The stringy texture of string cheese is created by the alignment of milk proteins during the kneading and stretching process. This process is similar to how gluten forms in bread, giving it its crumb shape. When making mozzarella, the curds are heated to 60 degrees Celsius or 140 degrees Fahrenheit. At this temperature, the milk proteins move around and line up together in a row. The cheese is then stretched and pulled by augers in a cooker stretcher, which further aligns the proteins and gives the cheese its stringy texture.

Mozzarella is naturally stringy, and this property is enhanced when it is made with low-fat milk and less moisture. The drier the mozzarella, the easier it is to pull apart, which is why string cheese is often made in stick form so that it can be easily peeled into strings. The stretching and pulling of the cheese during processing also contribute to its stringy texture.

The manufacturing process of string cheese involves aligning the proteins in the cheese through heating, stretching, and pulling, making it stringy. This process is similar to the traditional method of making korbáčiky, a salty sheep's milk cheese from Slovakia. Korbáčiky is made by hand-pulling steamed sheep's cheese into strings and then braiding them together.

The first string cheese snack was invented in Wisconsin in 1976 by Frank Baker. It is made with mozzarella cheese, milk, culture, and rennet, an enzyme that turns milk into thick curds. The low-moisture content and stretching process of the cheese contribute to its stringy texture, making it a popular snack that can be easily pulled into strips and eaten.

Gorgonzola Cheese: A True Taste of Italy's Lombardy Region

You may want to see also

Explore related products

The cheese is stretched and pulled by augers in a cooker stretcher while being heated to 60°C

The manufacturing process of string cheese is what gives it its characteristic stringiness. String cheese is made by stretching and pulling the cheese with augers in a cooker stretcher while heating it to 60°C. This process is called the pasta filata method, and it involves mechanically aligning the milk proteins to make them stretchy.

The cooker stretcher is a machine that uses augers to stretch and pull the cheese while heating it to the desired temperature. This process is crucial in developing the stringy texture of the cheese. By stretching and heating the cheese, the milk proteins are able to line up and form a row, allowing the cheese to be peeled into strings or strips.

The pasta filata method is commonly used in the production of mozzarella cheese, which is the primary type of cheese used in string cheese. Mozzarella is naturally stringy, and its stringiness is enhanced by reducing milk fat and moisture content. The low-moisture mozzarella cheese naturally forms into strings, and the stretching process further increases its stringiness.

After the cheese has been stretched and heated in the cooker stretcher, it is then pumped into an extruding machine. This machine shapes the cheese into the familiar tubular form of string cheese. The extruded cheese is then cut into the desired length and packaged for consumption.

The process of heating and stretching the cheese in the cooker stretcher is a critical step in creating the unique texture and stringiness of string cheese. By aligning the milk proteins, the cheese becomes stretchy and can be easily pulled apart into strings, making it a perfect snack for both kids and adults.

Chili Dogs: Best With Nacho Cheese?

You may want to see also

The type of milk used usually comes from an aged goat or sheep

While string cheese is made from mozzarella, the type of milk used in its production can vary. The "big three" types of milk used in cheese production are cow's milk, goat's milk, and sheep's milk. The choice of milk ultimately depends on the desired flavour, texture, and nutritional profile of the final product.

Goat's milk cheeses generally fall into one of two categories: those with a limestone-y and citrusy flavour profile, and those with a muskier, barnyard-like taste. Younger goat cheeses tend to exhibit the former profile, while more aged goat cheeses are associated with the latter.

Sheep's milk, on the other hand, produces cheese with a sweeter, creamier flavour and a higher fat content. Some common tasting notes in sheep's milk cheeses include candy corn, sweet cream, and a waxy lanolin flavour reminiscent of wool.

Goat's and sheep's milk cheeses are more expensive than cow's milk cheeses due to the lower milk yield per animal per day for goats and sheep. Additionally, these alternative milk sources have been marketed as artisanal and small-scale, with claims of better animal treatment, which has led to a growing trend of consumers switching from cow's milk dairy products to those derived from goat's or sheep's milk.

The Making of Snowdonia Cheese: A Welsh Delicacy

You may want to see also

Frequently asked questions

The type of milk used to make string cheese usually comes from aged goats or sheep. However, in the Marquesas Islands, a popular variety of string cheese is made from buffalo milk.

String cheese is made by heating mozzarella to 60°C (140°F) and then stretching it so that the milk proteins line up. It is then possible to peel strings or strips from the larger cheese.

Fresh mozzarella is kept in water or brine, while string cheese is made with low-moisture milk and is dried out.

Yes, string cheese is 100% mozzarella cheese.

String cheese gets its name because it can be eaten by pulling strips of cheese from the cylinder along its length and eating these strings.