Brie is a soft, creamy cheese with a distinctive white rind, and is a beloved delicacy worldwide. But what is Brie cheese casing made of? The rind is a type of mould, usually Penicillium candidum, which is completely edible and safe to consume. The mould is sprayed on early in the production process and forms a white rind that contributes to the overall flavour and texture of the cheese.

| Characteristics | Values |

|---|---|

| Edibility | Edible |

| Colour | White |

| Texture | Thick, Fluffy, Firm, Dried, Hardened |

| Composition | Fungus, Mould, Bacteria |

| Taste | Nutty, Buttery |

| Ingredients | Penicillium Camemberti, Penicillium Candidum |

| Safety | Harmless, Beneficial |

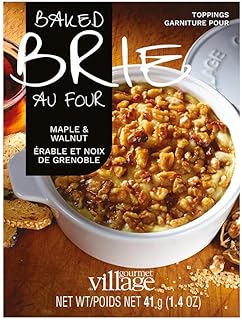

Explore related products

What You'll Learn

Brie cheese rind is edible

Brie cheese is a creamy, whitish cheese with a fluffy white rind and a gooey, soft, creamy, and smooth interior. It is a genuine delicacy and is famous for its mild, buttery flavor. Brie is traditionally made from cow's milk but can also be made from goat's milk. The rind is edible and is made from mold.

The rind of Brie cheese is typically safe to eat and is believed to be beneficial for the immune system. It is formed from a mold, usually Penicillium candidum or Penicillium Camemberti, that is sprayed on early in the production process. This mold forms a white rind that contributes to the cheese's overall flavor and significantly alters its texture. The rind is also essential in protecting the cheese, helping to prevent harmful organisms from contaminating it.

While the rind is generally considered edible and safe, some people may prefer to remove it before consuming the cheese. This is a matter of personal preference, and there is no harm in consuming the rind along with the cheese. In fact, some sources encourage eating the rind, as it adds to the flavor and textural experience of the cheese.

The process of making Brie cheese involves adding enzymes and rennet to milk, which can be either raw or pasteurized, to help it coagulate and curdle. A yeast culture is also added to encourage the growth of the white mold. The curds are then placed into molds, and the cheese is brined to regulate acidity and prevent excess mold growth. The rind forms as the mold blooms, and this process is repeated until the Brie is ready.

Overall, the rind of Brie cheese is an edible, safe, and flavorful part of the cheese. It is created through a careful process of mold cultivation and contributes to the unique characteristics of Brie.

The Mystery of White Cheese: Ingredients and Process

You may want to see also

It's made from moulds and bacteria

Brie is a soft and creamy cheese known for its mild, buttery flavour. It is traditionally made from cow's milk, although goat's milk can also be used. The cheese is aged in large wheels or rounds, with a thick, white rind. This rind is formed from moulds and bacteria, which are essential to the cheese-making process.

The mould used in Brie production is typically Penicillium candidum, a fungus that contributes to the cheese's flavour and texture. This mould is sprayed on early in the production process and forms a white rind as it grows. The rind is edible and safe to consume, and it is believed to be beneficial for the immune system. It also helps protect the inner cheese from harmful organisms that could cause contamination.

In addition to mould, bacteria are also used in Brie production. After milk and rennet (an enzyme) are added to the mixture, it is cut and ladled into moulds, and excess whey is drained off. The cheese is then brined to prevent excess mould growth and regulate acidity. This process is crucial in achieving the desired smooth flavour of Brie.

The rind of Brie is a result of the mould and bacteria interacting with the cheese during production. It is a natural and safe part of the cheese, contributing to both its flavour and texture. The rind is also important in protecting the inner cheese from contamination, ensuring that Brie can be enjoyed as a delicious and safe treat.

Mozzarella Cheese: Where to Buy the Best Buffalo-Made Product

You may want to see also

The mould is usually Penicillium candidum

Brie is a soft and creamy cheese known for its mild, buttery flavour. It is traditionally made from cow's milk and aged as large wheels or rounds. The cheese-making process involves adding enzymes and rennet to the milk, helping it coagulate and curdle. A yeast culture is also added to foster the growth of the white mould, Penicillium candidum, which is responsible for the formation of Brie's characteristic rind.

Penicillium candidum is a type of mould commonly used in cheesemaking. It is sprayed on early in the production process of Brie, contributing to the cheese's overall flavour and significantly altering its texture. This mould forms a white, bloomy rind that grows naturally and is safe and tasty to consume. The rind is the result of the mould blooming and being patted down repeatedly until the Brie is ready for consumption.

The mould Penicillium candidum plays a crucial role in the development of Brie's unique characteristics. By forming a protective layer around the cheese, the rind helps to preserve the inner cheese and enhance its flavour. The mould also contributes to the smooth and creamy texture of Brie, creating a contrast between the soft outer layer and the firmer centre.

While the white mould rind of Brie is generally considered safe and edible, some people may prefer to remove it before consumption. This preference may be influenced by cultural norms, personal taste, or sensory factors such as texture and appearance. However, it is important to note that removing the rind can alter the overall taste and textural experience of the cheese.

The mould Penicillium candidum is not only essential to the characteristics of Brie but also contributes to its versatility in culinary applications. Brie is commonly used in both savoury and sweet dishes. It can be baked, melted, or spread across bread, crackers, or fruits, making it a versatile ingredient in appetizers, main courses, and desserts.

Wisconsin's Fresh Cheese: Best Places to Visit

You may want to see also

Explore related products

The rind is hardened outer layers of cheese

The rind is a crucial part of Brie cheese, and it is created through a delicate process that involves the interaction of various elements. While it may seem like a mere hardened outer layer, it plays a significant role in the cheese's flavour and texture.

The rind of Brie cheese is formed through a natural process where moulds and bacteria interact with the cheese's surface. This process results in the development of a dried, hardened outer layer that distinguishes the rind from the softer inner cheese. The mould, typically Penicillium candidum or Penicillium Camemberti, is essential in giving Brie its characteristic flavour and texture. This "white mould" forms a fluffy, white rind that is not only edible but also contributes to the overall taste experience.

The process of creating the rind begins with the production of Brie cheese itself. Brie is traditionally made from cow's milk, although goat milk is sometimes used as well. The milk is mixed with enzymes, rennet, and a yeast culture, which help with coagulation and curdling. The mixture is then cut and ladled into moulds, and excess whey is drained off. The curds are shaped and brined to regulate acidity and prevent excess mould growth.

After the initial cheese formation, the rind development occurs. The cheese is allowed to rest, encouraging the rind to bloom and enhancing the cheese's flavour and texture. The mould, which is either sprayed on or forms naturally, creates a white, bloomy rind that is safe and tasty to consume. This process can take 4-5 weeks, with the Brie progressing from firm to ripe and developing a softer, almost runny consistency.

The rind of Brie is not just a protective outer layer but an integral part of the cheese's character. It is through the complex interaction of mould, bacteria, and cheese that Brie acquires its unique flavour and texture profile. The rind's hardened nature serves as a barrier, protecting the soft inner cheese while also enhancing its overall sensory experience.

Humboldt Fog Cheese: A Taste of Northern California

You may want to see also

It's safe to eat and good for the immune system

Brie is a soft cow's milk cheese that originated in the Brie region of northern France. It is pale yellow with a white rind of edible mould. The mould that forms the rind is called Penicillium Camemberti, a harmless fungus that gives Brie its unique taste. This mould is safe to eat and is believed to be beneficial for the immune system.

The Brie-making process involves adding the enzyme rennet to milk, along with salt and bacteria known as cheese cultures. The mixture is then left to ripen for about a month. During this ripening process, the white mould forms the rind of the cheese. This mould is safe to consume and is different from the mould that grows on other foods, which can indicate spoilage.

While Brie is generally safe to eat, there are a few safety considerations to keep in mind. Firstly, it is important to ensure that the Brie is made from pasteurised milk, especially for individuals who are pregnant, immunocompromised, or allergic to milk protein. Pasteurisation is a process of heat-treating milk to destroy harmful pathogens, such as Salmonella. Organic Brie, for example, may not be pasteurised, and it is important to check the packaging to ensure the cheese has undergone this process.

Additionally, it is crucial to store Brie properly to prevent the growth of unsafe mould. Brie should be stored in airtight packaging in the refrigerator and consumed within a few weeks of opening. If any blue or green mould appears on the cheese, it should be discarded as it indicates spoilage.

In terms of nutritional benefits, Brie is a high-fat, nutrient-rich cheese. It contains protein, vitamins, and minerals. Vitamin A, found in Brie, is particularly beneficial for maintaining a healthy immune system, promoting healthy skin and hair. Therefore, while enjoying the creamy taste and texture of Brie, one can also benefit from its positive impact on the immune system.

Cheese Dip: What's in Queso?

You may want to see also

Frequently asked questions

Brie is a soft and creamy cheese known for its mild, buttery flavour. It is traditionally made from cow's milk and aged as large wheels or rounds.

The casing of Brie cheese, also known as the rind, is made from a mould that is sprayed on early in the production process. This mould is called Penicillium candidum and forms a white rind that contributes to the cheese's overall flavour and significantly alters its texture.

Yes, the casing of Brie cheese is edible. In fact, eating the rind is encouraged as it is believed to be beneficial for the immune system and provides additional flavour.

Brie is a great addition to any cheese board. It can be served with nuts, dried fruit, crackers, and a crusty baguette. It also goes well with white wines like Chardonnay, Sauvignon Blanc, and Champagne.