Parmesan cheese is traditionally made from cow's milk, which is combined with whole milk and naturally skimmed milk. The milk is then heated in copper vats, with additional ingredients like whey and rennet added to form the curd. This process is what gives Parmesan its distinctive flavour and texture, which can be imitated by other cheeses, but never truly replicated.

| Characteristics | Values |

|---|---|

| Type of milk | Cow's milk |

| Milk combination | Whole milk and naturally skimmed milk |

| Milk origin | Imported |

Explore related products

What You'll Learn

Parmesan is made from cow's milk

Parmesan is traditionally made from cow's milk. It is made by combining whole milk and naturally skimmed milk, which is then distributed into copper vats for heating. During the two-step heating process, additional ingredients like whey and rennet are added to form the curd.

The Cheesy Truth: Burger King's Melty Options

You may want to see also

Cow's milk is combined with whole milk and naturally skimmed milk

Parmesan cheese is traditionally made from cow's milk, which is combined with whole milk and naturally skimmed milk. The milk is then distributed into copper vats for heating, during which additional ingredients like whey and rennet are added to form the curd. This two-step heating process is what gives Parmesan its distinctive flavour.

Cow's milk is also used to make other cheeses, such as Gouda, which is dense and nutty, and Muenster, which is an American cheese made from pasteurised cow's milk. Munster, a French cheese, is similar but made from unpasteurised cow's milk and may have a higher lactose level.

In contrast, Pecorino Romano and Romano are made from sheep's milk and have a much saltier flavour profile than Parmesan.

Pepper Jack Cheese: Spicy, Savory, and Sensational

You may want to see also

Additional ingredients like whey and rennet are added to form the curd

Parmesan cheese is traditionally made from cow's milk. During the cheese-making process, whole milk and naturally skimmed milk are combined and then distributed into copper vats for heating. Additional ingredients like whey and rennet are added to form the curd. The curd is then heated in a two-step process.

The whey is the liquid part of the milk that is left over after the milk has been curdled and strained. It is rich in lactose, protein, vitamins, and minerals. Rennet is a complex mixture of enzymes produced in the stomachs of ruminant animals, which is used in cheese-making to curdle milk.

The curd is then aged for at least 12 months, during which time the natural fermentation of the cow's milk gives the cheese its distinctively sweet taste.

Green Enchiladas: Choosing the Perfect Cheese for Your Dish

You may want to see also

Explore related products

Parmesan is aged for at least 12 months

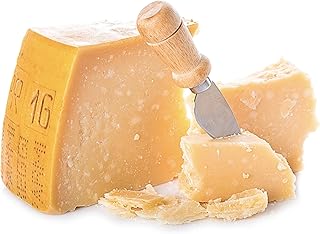

Parmesan is traditionally made from cow's milk and is aged for at least 12 months. The milk is a combination of whole milk and naturally skimmed milk, which is then distributed into copper vats for heating. During the two-step heating process, additional ingredients like whey and rennet are added to form the curd. The longer the cheese is aged, the sweeter it will taste. For example, Copper Kettle cheese is aged for 16 months in copper vats, which creates a distinctively sweet flavour through the natural fermentation of cow's milk.

Parmesan should not be confused with Pecorino Romano, which is made from sheep's milk and has a much saltier flavour profile. Romano is also made from cow's milk, but it is a different cheese to Parmesan, with a saltier flavour.

Chipotle's Cheese: A Comprehensive Guide to Their Cheesy Delights

You may want to see also

Pecorino Romano and Romano are made from cow's milk too, but have a saltier flavour profile

Parmesan cheese is traditionally made from cow's milk, which is combined with whole milk and naturally skimmed milk, then heated in copper vats. However, Pecorino Romano and Romano are made from cow's milk too, but have a saltier flavour profile.

Pecorino Romano is made from domestic cow's milk, while Romano is made from imported cow's milk. If you plan on substituting Romano for Parmesan in a dish, use less than the recipe calls for as it can overwhelm the overall taste of the food.

Lasagna's Best Cheese: Finding the Perfect Match

You may want to see also

Frequently asked questions

Parmesan is traditionally made from cow's milk.

Whole milk and naturally skimmed milk are combined and then distributed into copper vats for heating. During the two-step heating process, additional ingredients like whey and rennet are added to form the curd.

Gouda, Muenster, Munster, Brie and Camembert are all made from cow's milk.