If you're interested in ageing cheese at home, there are a few things you need to know about the room you'll be using. While some cheeses are still aged in ancient caves, most are now aged in walk-in coolers or climate-controlled rooms. The two primary factors that determine the suitability of a space for ageing cheese are temperature and humidity.

| Characteristics | Values |

|---|---|

| Temperature | Between 45º and 55º F |

| Humidity | Depending on the type of cheese, you will need more or less humidity. For instance, a Parmesan-style cheese will need a fairly low humidity level, a bloomy rind cheese like Brie or Camembert will need a fairly high humidity level |

| Location | On the North side will exclude solar gain problems |

| Frost line | Building below grade will use cooler earth temps for cooling |

| Insulation | Insulation of walls and ceiling to isolate from other heated spaces |

| Opening of doors | How much traffic in and out of the room |

| Heat generated | From motors, lights, etc. |

Explore related products

What You'll Learn

- Temperature: The optimal temperature for aging cheese is between 45º and 55º F

- Humidity: Different cheeses require different humidity levels

- Location: The room should be on the north side to avoid solar gain issues

- Insulation: Walls and ceilings should be insulated to maintain a constant temperature

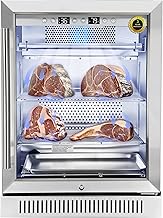

- Equipment: A wine refrigerator with temperature control is a good option for aging cheese

Temperature: The optimal temperature for aging cheese is between 45º and 55º F

While some cheeses, like Roquefort, are still aged in ancient caves, most cheeses are now aged in walk-in coolers or climate-controlled rooms. These spaces are carefully monitored to simulate the conditions provided by those caves to ancient cheesemakers. The two primary factors that determine the suitability of a space for ageing cheese are temperature and humidity.

Temperature: The optimal temperature for ageing cheese is between 45º and 55º F. This should remain as constant as possible. To achieve this, consider the location of the room, the frost line, the insulation of walls and ceilings, the opening of doors, and the heat generated from motors and lights.

The first option for storing cheese is a wine refrigerator. These can often be found second-hand for less than $100 and are just about perfect for ageing cheese. Try to find one with a temperature control feature. Once you have your wine refrigerator, the next thing you'll need is a thermometer. A cheese or meat thermometer will not work in this scenario; you need one that measures ambient temperature. A basic room or porch thermometer will work just fine, and some wine refrigerators come with one.

If you do not have a cellar ready-made, much of the above can apply to building your own purpose-built room. Just remember that different cheeses have different requirements and each room will have its own special plan depending on what you are ageing in it.

Garlic Knots: Which Cheeses Melt and Stretch the Best?

You may want to see also

Humidity: Different cheeses require different humidity levels

If you are making several different types of cheese but ageing them in the same space, you may need to build separate micro-climates within that space to account for the different humidity requirements.

Aging spaces are carefully monitored to simulate the conditions provided by ancient caves to cheesemakers. These caves provided a closed environment that was consistently cool year-round, even in hot climates. Modern cheese-ageing spaces are often built underground or dug into hillsides because the earth helps to provide natural insulation and climate control.

The best option for storing cheese is a wine refrigerator, which can often be found second-hand for less than $100. These refrigerators are ideal for ageing cheese as they provide a closed environment with a consistent temperature.

Cheese and Chili: Melting Pot of Flavors

You may want to see also

Location: The room should be on the north side to avoid solar gain issues

When it comes to ageing cheese, the two primary factors that determine the suitability of a space are temperature and humidity. Most cheeses are aged in walk-in coolers or climate-controlled rooms. These spaces are carefully monitored to simulate the conditions provided by ancient caves, which were used for hundreds of years to age cheese.

The location of your cheese-ageing room is important. The room should be on the north side to avoid solar gain issues. This will help to keep the room cool, as will building the room underground or into a hillside, as the earth provides natural insulation and climate control. If you don't have a cellar, you can build a purpose-built room. Other factors to consider are the insulation of walls and ceilings, how much traffic there will be in and out of the room, and the heat generated from motors and lights.

Temperature is key, and the optimal range is between 45º and 55º F. This should remain as constant as possible. If you are making several different types of cheese but ageing them all in the same space, you may need to build separate micro-climates within that space. For instance, a Parmesan-style cheese will need a fairly low humidity level, while a bloomy rind cheese like Brie or Camembert will need a fairly high humidity level. A waxed or vacuum-sealed cheese won't be affected by humidity levels as they are well contained.

Cheese and Spaghetti: The Perfect Melty Combination

You may want to see also

Explore related products

Insulation: Walls and ceilings should be insulated to maintain a constant temperature

Insulation is a key factor in maintaining a constant temperature in a room for ageing cheese. Walls and ceilings should be insulated to isolate the room from other heated spaces. This will help to keep the temperature cool and consistent, which is ideal for ageing cheese.

The optimal temperature range for ageing cheese is between 45º and 55º F. This temperature should be maintained as constantly as possible. To achieve this, the location of the room should be considered. Building the room below ground will help to utilise cooler earth temperatures for cooling.

In addition to insulation, other factors that can affect the temperature of the room include the amount of traffic in and out of the room, heat generated from motors and lights, and the opening of doors. By considering these factors and implementing effective insulation, a constant temperature can be maintained in the room for ageing cheese.

Some modern cheese-ageing spaces are built underground or dug into hillsides, as the earth provides natural insulation and climate control. This helps to maintain the cool, consistent temperatures needed for ageing cheese.

Non-Dairy Cheese: Exploring Vegan Alternatives

You may want to see also

Equipment: A wine refrigerator with temperature control is a good option for aging cheese

The two primary factors that determine the suitability of a space for ageing cheese are temperature and humidity. While some cheeses, like Roquefort, are still aged in ancient caves, most cheeses are aged in walk-in coolers or climate-controlled rooms. These spaces are carefully monitored to simulate the conditions provided by those caves to ancient cheesemakers.

A wine refrigerator with temperature control is a good option for ageing cheese. You can often find these second-hand for less than $100, and they are just about perfect for ageing cheese. Once you have your wine refrigerator, the next thing you'll need is a thermometer. A cheese or meat thermometer will not work in this scenario; you need one that measures ambient temperature. A basic room or porch thermometer will work just fine, and some wine refrigerators come with one.

If you do not have a cellar ready-made, you can build your own purpose-built room. Remember that different cheeses have different requirements, and each 'cave' will have its own special plan depending on what you are ageing in it. The optimal range of temperature is between 45º and 55º F and should remain as constant as possible. To obtain this, consider the location of the cave, the frost line, the insulation of walls and ceilings, the opening of doors, and the heat generated from motors and lights.

If your ageing space has a humidity controller, that's great, but most don't. And if you're making several different types of cheese but ageing them all in the same space, you may need to build separate micro-climates within that space. For instance, a Parmesan-style cheese will need a fairly low humidity level, a bloomy rind cheese like Brie or Camembert will need a fairly high humidity level, and a waxed or vacuum-sealed cheese won't care about the humidity level in your ageing space since they are pretty well contained.

Bocconcini: A Beginner's Guide to This Fresh, Soft Cheese

You may want to see also

Frequently asked questions

The optimal temperature for aging cheese is between 45º and 55º F.

This depends on the type of cheese you are making. For example, a Parmesan-style cheese will need a fairly low humidity level, while a bloomy rind cheese like Brie or Camembert will need a fairly high humidity level.

No, you can use a wine refrigerator, which can often be found second-hand for less than $100.