Yogurt and cheese are primarily made from bacteria, specifically Lactobacillus, Bifidobacterium, and Streptococcus. However, the production of certain types of cheeses, such as blue cheese and Camembert, may also require fungal cells, specifically mold cultures like Streptococcus thermophilus. The presence of mold in yogurt and cheese can be a concern, as it may indicate the presence of harmful toxins and bacteria. In some cases, moldy yogurt has been linked to gastrointestinal issues in consumers. Therefore, while some molds are safe to consume, it is generally recommended to discard moldy yogurt and soft cheeses, as the mold may be growing below the surface and pose potential health risks.

| Characteristics | Values |

|---|---|

| Are yogurt and cheese made of mold cells? | Yogurt is made from bacteria, specifically Lactobacillus bulgaricus and Streptococcus thermophilus. Cheese is also made from bacteria, but certain types of cheese, such as blue cheese and Camembert, require the addition of mold cultures like Penicillium to develop their characteristic flavor and texture. |

| What happens if you eat moldy yogurt or cheese? | According to the USDA, moldy yogurt should be discarded as it may be contaminated below the surface. For hard cheeses like Asiago, Pecorino, Parmesan, and Cheddar, it is generally safe to cut off at least 1 inch around and below the mold spot. Soft cheeses with mold, such as Brie, Camembert, and cottage cheese, should be thrown away. |

| How to prevent mold growth in yogurt and cheese? | Mold thrives in warm and humid conditions. To prevent mold growth, maintain proper refrigeration temperatures and ensure cleanliness in storage and handling. |

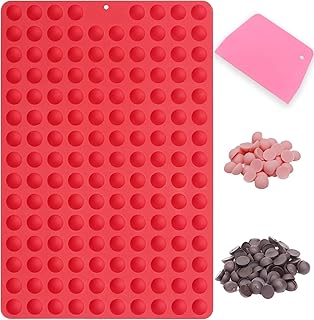

Explore related products

What You'll Learn

Blue cheese is made using Penicillium mould

Yogurt and cheese are primarily made from bacteria, specifically Lactobacillus, Bifidobacterium, and Streptococcus. These bacteria are prokaryotic cells, which means they lack a nucleus and other membrane-bound organelles. When milk is heated and then cooled, these bacteria are introduced as starter cultures, which ferment the lactose in the milk into lactic acid through a process called fermentation. This process causes milk proteins, particularly casein, to curdle, forming the thickened texture of yogurt and the curds used in cheese production.

While yogurt is typically made using bacterial strains, cheese production often involves the use of various types of bacteria and molds. For instance, cheddar cheese is produced with specific strains of Lactococcus lactis, while blue cheese involves the introduction of Penicillium mold for its characteristic taste and appearance.

Blue cheese is made using Penicillium mold, specifically the species Penicillium roqueforti, which is responsible for the distinctive veins, flavor, aroma, and appearance of blue cheeses. This mold breaks down proteins and fats, yielding the textures, aromas, and flavors associated with blue cheese. The blue-green color of the mold is derived from pigmented spores formed by fungal growth.

Penicillium roqueforti is a diverse species found in many distinct blue cheeses, such as Roquefort, Gorgonzola, and Stilton. It is also found in other food products and the natural world. The environment, cheesemaking operations, and aging conditions can influence the selection of certain subspecies of Penicillium roqueforti.

Recent studies have explored the potential to generate new colored strains of Penicillium roqueforti by altering the DHN-melanin biosynthesis pathway. These color mutants can change the appearance of the cheese without significantly increasing mycotoxin levels. These findings offer exciting prospects for future cheese manufacture, potentially leading to the creation of new 'non-blue' colored mold-ripened cheeses.

Fromunda Cheese: A Recipe's Secret Weapon

You may want to see also

Yogurt and cheese are primarily made from bacteria

When milk is heated and then cooled, these bacteria are introduced as starter cultures. They ferment lactose, the sugar in milk, into lactic acid through a process called fermentation. This lactic acid production causes the milk proteins, particularly casein, to denature and curdle, forming the thickened texture of yogurt and the curds used in cheese production. Yogurt is typically made using key bacterial strains such as Lactobacillus bulgaricus and Streptococcus thermophilus. These bacteria thrive in warm conditions and convert lactose into lactic acid, resulting in the creamy texture and tangy flavor of yogurt.

Cheese production also involves the use of bacteria, but it may additionally require fungal cells. Bacteria are responsible for the initial acidification of the milk, while fungal cells, or mold cultures, contribute to the flavor and texture of certain types of cheeses, such as blue cheese and Camembert. For example, the production of cheddar cheese uses specific strains of Lactococcus lactis, while blue cheese involves the introduction of Penicillium mold for its characteristic taste.

It is important to note that mold can also be a contaminant in yogurt and cheese, leading to spoilage and potential health risks. Molds are microscopic fungi that can produce spores and grow on various food products, including yogurt and cheese. In some cases, molds can produce mycotoxins, which are poisonous substances that can cause illness. Therefore, it is recommended to discard moldy yogurt and soft cheeses, as the mold may be growing below the surface and pose a risk to human health.

The Cheesy Truth Behind Olive Garden's Signature Dish

You may want to see also

Some moulds produce poisonous substances

Yogurt and cheese are primarily made from bacteria, specifically species belonging to the genera Lactobacillus, Bifidobacterium, and Streptococcus. These bacteria are prokaryotic cells, meaning they lack a nucleus and other membrane-bound organelles. When milk is heated and then cooled, these bacteria are introduced as starter cultures. They ferment lactose, the sugar in milk, into lactic acid through a process called fermentation. This lactic acid production causes the milk proteins, particularly casein, to denature and curdle, forming the thickened texture of yogurt and the curds used in cheese production.

While yogurt and cheese are made from bacteria, certain types of cheese incorporate mold in their production. For example, blue-veined cheeses such as Roquefort, Blue, Gorgonzola, and Stilton are created by the introduction of P. roqueforti or Penicillium roqueforti spores. Cheeses such as Brie and Camembert have white surface molds. In addition, Mucor spp. are common spoilage agents of yogurt and cheese.

Some molds produce mycotoxins, which are poisonous substances that can make you sick. Mycotoxins can grow on a variety of different crops and foodstuffs, including cereals, nuts, spices, dried fruits, apples, coffee beans, and celery. They can also be found in grape juice and other produce. Mycotoxins can cause a range of adverse health effects, from acute poisoning to long-term issues such as immune deficiency and cancer.

It is important to note that not all molds produce mycotoxins, and some molds are safe to consume. For example, molds found on hard salami, dry-cured country hams, and certain types of cheese like Brie are generally considered safe to consume. However, it is always a good idea to exercise caution when it comes to moldy food. The USDA has a chart titled "Moldy Food: When to Use, When to Discard" to guide consumers on how to handle moldy food items.

The Authentic Manchego Cheese: Made in La Mancha

You may want to see also

Explore related products

$17.97

Soft cheeses with mould should be discarded

While yogurt and cheese are primarily made from bacteria, molds are also used in the production of cheese. For example, the introduction of Penicillium mold is used to give blue cheese its characteristic taste.

Molds are a common spoilage agent of yogurt and cheese. Some molds produce mycotoxins, which can be harmful to humans. For example, Mucor circinelloides can cause nausea, vomiting, and diarrhea. In 2013, Chobani recalled several varieties of its Greek yogurt after consumers found mold in the containers and reported gastrointestinal problems.

The USDA recommends discarding moldy yogurt because foods with high moisture content can be contaminated below the surface. However, the USDA is not concerned about molds on hard salami and dry-cured country hams, where the mold can be scraped off, or on Brie, where the mold is eaten.

When it comes to moldy cheese, the general rule is that fresh soft cheeses, such as ricotta, mascarpone, and chèvre, should be discarded since the mold has likely penetrated deep into the cheese and negatively impacted its flavor. Harder, aged cheeses, like aged Cheddar or Parmesan, can have the mold scraped away. Black or gray mold should be cut away more generously to ensure that any cheese that might be impacted is removed. Any moldy cheese that smells of ammonia or is both moldy and wet should be discarded.

Cheese Puffs: A Snack with a Historical Twist

You may want to see also

Hard cheeses can be consumed after removing mould

Yogurt and cheese are primarily made from bacteria, specifically Lactobacillus, Bifidobacterium, and Streptococcus. These bacteria are prokaryotic cells, which means they lack a nucleus and other membrane-bound organelles. During the fermentation process, these bacteria convert lactose, the sugar in milk, into lactic acid, resulting in the desired food products.

While the production of yogurt and cheese relies on bacteria, molds can also play a role. For example, the introduction of Penicillium mold is used in blue cheese production. Additionally, spoilage molds, such as Mucor and Penicillium, can cause dairy products to become contaminated and unsuitable for consumption.

In the case of hard cheeses, it is generally considered safe to consume the cheese after removing the mold. Dr. Francisco Diez-Gonzalez, a professor at the University of Georgia Center for Food Safety, explains that the mold's mycelium cannot penetrate deep into hard cheeses, and the lack of moisture prevents the diffusion of toxins. The FDA recommends removing at least one inch of cheese around and below the mold spot to ensure that all potential toxins are eliminated. However, it is important to note that if the cheese is entirely covered in mold or too small to cut one inch below the surface, it should be discarded.

On the other hand, soft cheeses, such as ricotta, cottage cheese, mascarpone, goat cheese, and feta, should be discarded if mold is present. The moisture in soft cheeses allows the mold to grow deeper, and toxins are released throughout the product.

While some molds on hard cheeses can be safely removed, it is always important to exercise caution. Different molds can have varying effects, and some may produce toxins that can cause allergic reactions or, in rare cases, make you ill. Therefore, it is recommended to follow food safety guidelines and use your best judgment when encountering mold on cheese or other food products.

Where Is Pancho's Cheese Dip Produced?

You may want to see also

Frequently asked questions

Yogurt and cheese are primarily made from bacteria, specifically Lactobacillus, Bifidobacterium, and Streptococcus. However, some cheeses like blue cheese and Camembert require the introduction of mold cultures like Penicillium to achieve their characteristic taste.

Bacteria convert lactose, the natural sugar present in milk, into lactic acid through a process called fermentation. This gives yogurt its tangy flavor and thick texture. In cheese production, bacteria are responsible for the initial acidification of the milk.

Molds are microscopic fungi that can produce mycotoxins, which are poisonous substances that can make you sick. Therefore, it is recommended to discard yogurt if mold is present as it may be growing below the surface. For hard cheeses like Cheddar, cutting off at least 1 inch around and below the mold spot is generally considered safe.

To prevent mold growth, maintain cleanliness in your refrigerator and on utensils. Clean the inside of the refrigerator regularly with a solution of baking soda and water, and rinse and dry thoroughly. Additionally, control humidity levels, as molds thrive in warm and humid conditions.