Brick cheese is a medium-soft, Wisconsin-made cheese that is formed into a rectangular brick shape. The cheese-making process is similar to American Cheddar, but it is cultured at a higher temperature, resulting in a higher fat content and a slightly altered protein structure. The cheese is made by heating raw milk to 162°F, then cooling it to 90°F before adding a starter culture of bacteria to begin the fermentation process. The curds are then cooked and cut into cubes, moulded into rectangles, and soaked in a brine solution. The cheese is then washed with a whey and water mixture and placed in an ageing room. After about a week, it is moved to a cold ageing room, where it spends anywhere from one week to several months.

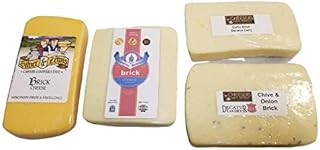

Explore related products

What You'll Learn

- Brick cheese is made in a similar way to American Cheddar, but at a higher temperature

- The curds are pressed with bricks, which gives the cheese its name and shape

- The cheese is washed and turned, then stored at a cold temperature

- It is ready to eat after two weeks, but can be stored for up to five months

- It has a sweet, mild flavour when young, but matures into a strong, pungent cheese with age

Brick cheese is made in a similar way to American Cheddar, but at a higher temperature

Brick cheese is a type of cheese that originated in Wisconsin, USA, and was first made by John Jossi in 1877. It is believed that Jossi was inspired by the Limburger cheese he had produced in factories in Richwood, Wisconsin, but he wanted to create a drier version. The name "Brick" comes from the original cheese-making process, in which artisans used bricks to press the moisture out of the cheese and give it its distinctive shape.

The process of making Brick cheese is similar to that of American Cheddar, but with some key differences. Firstly, the milk for Brick cheese is heated to a higher temperature of 88°F (31°C). This small change results in a slightly higher fat content and a marginally altered protein structure in the final product. The cheese also has a softer texture and a sharper finish than regular Cheddar.

To make Brick cheese, 4 gallons of milk are heated to 88°F (31°C). The milk should be heated slowly and stirred well to ensure even heating. Once the desired temperature is reached, a culture and B. linens are added. The powder is sprinkled over the surface of the milk to prevent clumping, and then it is allowed to rehydrate for about 2 minutes before stirring. The milk is then left to ripen for 10 minutes to allow for slow acid development, which gives the cheese its sweet taste.

After the ripening process, liquid rennet is added, and the mixture is allowed to set. Once the curds have formed, they are cut and stirred gently to release moisture. The curds are then allowed to settle under the whey, and the whey is removed down to the curd level. The curds are transferred to a sanitized mould and allowed to drain for 15 minutes with no weight. They are then turned and weighed down with 5 lbs of weight (2.5 qts of water) to form the traditional brick shape of 5"x10".

The cheese is then placed on wooden shelves and washed with a whey and water mixture. It is turned periodically to ensure even washing. In the curing room, the aged Brick is maintained at 68-70°F and 90-95% moisture. It is washed and rubbed daily with a light brine for 7 to 10 days to encourage bacterial growth on the surface. After this initial curing period, the cheese is simply turned daily for another 7-10 days. It is then wrapped and stored in cold storage at 42°F until ready for consumption, which is typically after 2-3 months of total ripening time.

History of Bronco Cheese Graters: When Were They Made?

You may want to see also

The curds are pressed with bricks, which gives the cheese its name and shape

The pressing process is carefully controlled to achieve the desired moisture level in the final product. Too little moisture will affect the cheese's texture and ripening process, so the curds are first allowed to settle under the whey before it is removed. The curds are then transferred to a sanitized mold, where they are left to drain for 15 minutes with no weight.

After the initial draining period, the curds are turned and a weight is added. The weight used is typically around 5 pounds, and this step helps to further remove moisture and give the cheese its characteristic shape. The traditional brick mold measures 5"x10", but larger or smaller molds can also be used, with the weight adjusted accordingly.

The pressing process is a key step in the cheese-making process, as it not only shapes the cheese but also influences its texture and overall quality. By using bricks to press the curds, cheese makers can control the moisture content, ensuring a consistent and desirable outcome. This technique has been passed down since the cheese's invention in 1877 by John Jossi, a Swiss-born American cheese maker, and remains a defining feature of the cheese's production.

The Story of Kaukauna Cheese: Wisconsin's Finest

You may want to see also

The cheese is washed and turned, then stored at a cold temperature

Once the cheese has been pressed and its shape has been formed, it is placed on wooden shelves and washed with a whey and water mixture. It is then turned and can be stored in cold storage for up to five months. After two weeks, it is considered ready for consumption. The US Code of Federal Regulations defines the fat and moisture content of brick cheese.

The curing process for brick cheese is a crucial step in its production. In the curing room, the aged brick is maintained at a temperature of 68-70°F (20-21°C) and a moisture level of 90-95%. The cheese is then washed and rubbed daily with a light brine solution for 7 to 10 days. This process encourages the growth of beneficial bacteria on the surface of the cheese, enhancing its flavour and texture. After this initial washing and rubbing phase, the cheese is simply turned daily for another 7 to 10 days.

To create the light brine solution, you can mix one to two tablespoons of salt with one cup of cool water. It is important to start with a lower salt concentration and gradually increase it if necessary to control mould growth. After the curing process, the cheese is wrapped and stored in a cold environment at 42°F (5.5°C) until it is ready for consumption. The total ripening time for brick cheese is typically two to three months.

The curing and cold storage process is essential in developing the distinctive flavour and texture of brick cheese. By controlling the temperature, humidity, and bacterial growth during curing, cheesemakers can ensure the cheese matures properly. The cold storage period allows the flavours to continue developing and enhances the overall quality of the final product.

Cheese Ingredients and Their Magic

You may want to see also

Explore related products

It is ready to eat after two weeks, but can be stored for up to five months

Brick cheese is ready to eat after two weeks, but it can be stored for up to five months. This American original, produced in Wisconsin, was first made by John Jossi in 1877. The cheese-making process is similar to American Cheddar, but it is cultured at a slightly higher temperature, resulting in a marginally higher fat content and a slightly altered protein structure. The final product is a slightly softer, sweet and mild-flavoured cheese that matures into a strong, ripe cheese with age.

The process of making Brick cheese is borrowed from white American Cheddar, although the resultant cheese is slightly softer and has a distinctly sharper taste. Many associate Brick cheese with Germany's surface-ripened Beer cheese or Beer Käse. The name "Brick" comes from the original cheese-making process, where artisans used bricks to press the moisture out of the cheese and give it its distinctive shape.

To make Brick cheese, milk is heated to 88°F (31°C), and then culture and b. linens are added. After allowing the milk to ripen for 10 minutes, liquid rennet is added. The curds are then allowed to settle, and the whey is removed. The curds are transferred to a sanitized mold to drain, and then turned and weighted to form the traditional brick shape.

In the curing room, the aged Brick is kept at 68-70°F and 90-95% moisture. It is washed and rubbed daily with a light brine for 7 to 10 days to encourage bacterial growth on the surface. It is then turned daily for another 7 to 10 days before being wrapped and cold-stored at 42°F until ready. The total ripening time is typically 2 to 3 months.

The Art of Semi-Soft Cheeses: A Step-by-Step Guide

You may want to see also

It has a sweet, mild flavour when young, but matures into a strong, pungent cheese with age

Brick cheese is a medium-soft cheese with a sweet and mild flavour when young. It is made in a large rectangular or brick shape. The colour ranges from pale yellow to white with an orange rind. The cheese-making process is similar to American Cheddar, but it is cultured at a slightly higher temperature, resulting in a marginally higher fat content and a slightly altered protein structure. The final cheese is relatively sweet with higher moisture.

The process of making Brick cheese is borrowed from white American Cheddar, although the resultant cheese is slightly softer and distinctly sharper-tasting. Many associate Brick cheese with Germany's surface-ripened Beer cheese or Beer Käse. The name "Brick" comes from the original cheese-making process, in which artisans used bricks to press the moisture out of the cheese.

As Brick cheese matures, its mild and sweet flavour changes to pungent and tangy with a touch of nuttiness. The cheese is placed on wooden shelves and washed with a whey and water mixture. It is then turned and can be stored in cold storage for up to five months. It is considered ready for consumption after two weeks.

To make Brick cheese, milk is heated to 88°F (31°C). Once the milk reaches the desired temperature, the culture and b. linens are added. The milk is allowed to ripen for 10 minutes to produce a sweet cheese. Then, liquid rennet is added. When the curds form, they are allowed to settle, and the whey is removed. The curds are then transferred to a sanitized mould and allowed to drain.

The Mystery of White Cheese: Ingredients and Process

You may want to see also

Frequently asked questions

Brick cheese is a medium-soft, Wisconsin-made cheese that is formed into a brick shape. It is best known as the traditional cheese for Detroit-style pizza.

Brick cheese is made by heating raw milk to 162°F, which pasteurizes it. It is then cooled to around 90°F before being pumped into open steel vats. A starter culture of bacteria is then added, which starts the fermentation process. After this, a substance called rennet is added, which triggers the curdling of the milk proteins, separating them from the liquid whey. The curds are then cooked for about 40 minutes to help firm the cheese and intensify its acidity. They are then cut into cubes, moulded into rectangular shapes, and pressed to squeeze out the whey.

Traditionally, the cheese curds are pressed with clay-fired bricks, which is where the cheese gets its name.

Young brick cheese has a sweet, mild, and earthy flavour and melts and slices well. Aged brick cheese has a nuttier, tangier flavour and a strong aroma.

Brick cheese can be stored in cold storage for up to five months and is considered ready to eat after two weeks.